Energy management

Monitoring audit in line with ISO 50001

In July 2022, uvex Winter Holding and the businesses uvex Arbeitsschutz, uvex safety gloves, uvex sports Lederdorn, B-S-A Gesellschaft für Kunststoffverarbeitung und -handel mbH and Filtral were successfully audited in line with ISO 50001:2018.

Focus on green energy and biogas

The uvex group has been making use of green energy since as early as 2014 and has been using biogas since 2017. In total, 100% of the electricity we purchase comes from renewable energy sources and also promotes new systems for renewable energies. In addition, the emissions generated when the gas is burned are offset. The income from the reduction certificates is invested in projects that aim to contribute to cutting CO2, without which these projects could not be realised.

These projects have a social aspect to them as well: for example, they ensure sustainable development in the local area and help to create jobs, as well as improving social, ecological and sanitary conditions.

Photovoltaic system in Burgfarrnbach

The new photovoltaic (PV) system in Burgfarrnbach has been connected to the grid since 5 October 2021. The new system was installed on the hall roof and provides approximately 97,000 kWh of solar energy per year, with an output of 99.9 kWp as well. The solar power is fed directly into the site’s own network, where it can then be used directly by Filtral.

In financial year 2021/22, the PV system had been in operation for 10 months: it generated 82,000 kWh of electricity and fed in a total of 49,000 kWh. Grid demand fell by 33,000 kWh. The CO2 saving amounts to 33 tons in comparison with the German electricity mix, although the annually announced CO2 saving comes in at around 40 tons compared with the German electricity mix. This PV system generates enough electricity to supply the equivalent of 30 households.

A conclusive assessment will be carried out after the first full year of operation.

uvex sports Austria moves to Neukirchen: energy-based upgrades

The building to be occupied is being upgraded for its planned start of use in the 2022/23 financial year. The construction measures include the installation of a photovoltaic system with an output of 29 kWp to cover the company’s own electricity requirements, as well as the connection to the municipal district heating supply. In this context, uvex sports Austria’s heating supply is secured by way of wood chips from sustainable forestry. In addition, the building will be insulated to minimize heat loss and bring it up to date with the latest technology. In terms of mobility solutions, two charging points for electric vehicles are also being installed.

Logistics and service centre in Rednitzhembach

On 27 September 2021, the uvex group marked the start of construction on a modern and sustainable new logistics and service centre in Rednitzhembach to the south of Nuremberg with a symbolic ground-breaking ceremony. The new building then started to take shape over the course of the autumn of that year. The building covers a total area of 35,000 square metres and includes an automated high-bay warehouse, an automated small parts warehouse, logistics areas for order picking, incoming and outgoing goods in addition to high-quality office space and administrative areas with a swish customer and visitor area. The construction project also included aspects such as a gatehouse and car park.

The German Sustainable Building Council (DGNB) has already issued a Gold level pre-certification for the new building. Heating for the building will be generated from two wood chip boilers, while a significant portion of the electricity requirement will be covered by a photovoltaic system installed on the roof of the high-bay warehouse. A living green roof will additionally cover the majority of the roof space, with as many photovoltaic modules as possible also being installed. In total, the PV installation offers an output of 750 kWp. Electric charging pillars are being installed in the car park as well.

The uvex group is also building the new facilities at the logistics and service centre, including the order picking facility and gatekeeper building, in line with the highly energy-efficient KfW40 standard. This means that they will use 60% less energy than a conventional new building.

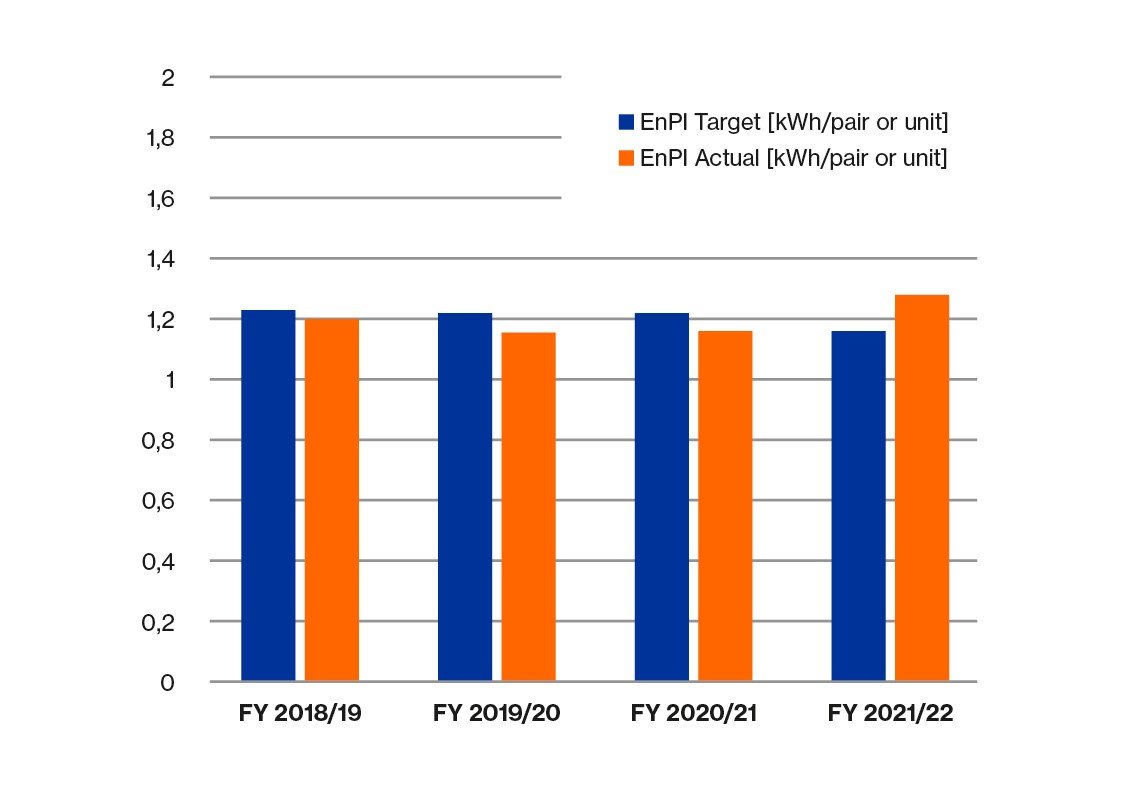

Development and target-setting for specific energy consumption within the scope of DIN EN ISO 50001

| GJ 2018/19 | GJ 2019/20 | GJ 2020/21 | GJ 2021/2022 | |

| Energy Performance Indicator (EnPI) Ziel (kWh/Stck) | 1,23 | 1,22 | 1,22 | 1,16 |

| Energy Performance Indicator (EnPI) Ist (kWh/Stck) | 1,10 | 1,07 | 1,08 | 1,28 |

After implementing improvement measures and increasing efficiency through the continuous improvement process, the key figure increased slightly due to an increased production volume of more complex and thus more energy-intensive products.